Bubble Alumina for Brick

Alumina raw materials are melted in an electric arc furnace at 2200℃. When pouring the melt out, blow the melt with high-pressure air to make the melt dispersed into small droplets. During the cooling process, the droplets form alumina hollow balls due to surface tension effects. The hollow balls are screened to remove fine powder and big fragments and particles. Iron is removed with the magnetic iron. Broken balls are removed with a ball selecting machine. Then the alumina hollow spheres are packed as the finished products.

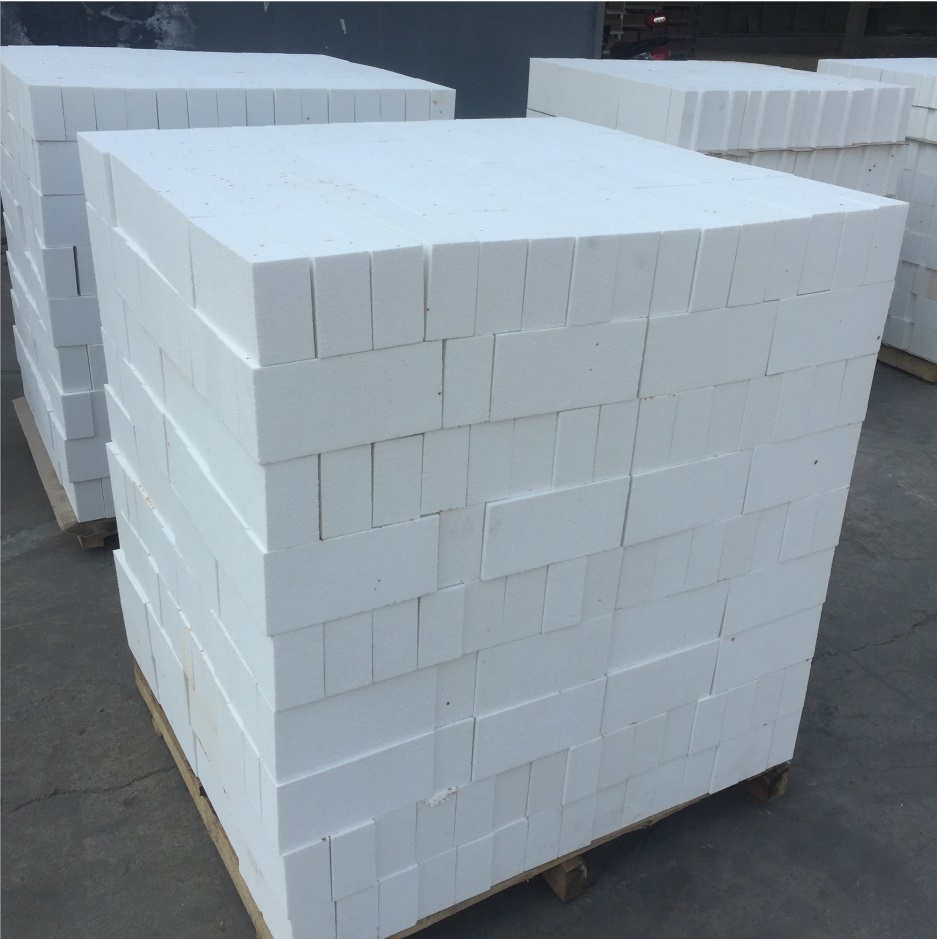

The Applications of Bubble Alumina brick:

Bubble Alumina Bricks are for applications up to 1800°C/3270°F. These bricks have excellent insulating properties and high hot strengths. Typical applications for Bubble alumina bricks include gas or electrically heated kilns and furnaces, and glass-making industries. insulation of kiln brick and ceramic tile linings in gas turbines, backup linings in reactors, and working linings in manufacturing high-purity quartz for the electronics industry

| Typical Anaysis | |

| Al2O3 | 99.2% |

| SiO2 | 0.8% |

| MgO | 0.05% |

| Na2O | 0.1% |

| Fe2O3 | 0.03% |

| CaO | 0.03% |

| Sizing | Bulk Density |

| 0 – 0,2 mm | 1000-1450 |

| 0 – 0,5 mm | 800-1100 |

| 0,5 – 1 mm | 650-850 |

| 0 – 1 mm | 700-1050 |

| 1 – 1,5 mm | 550-800 |

| 0 – 2 mm | 650-1000 |

| 1,5 mm – 2 mm | 550-800 |

| Sizing | Bulk Density |

| 0 – 3 mm | 650-950 |

| 0 – 5 mm | 600-900 |

| 1 – 2 mm | 550-800 |

| 1 – 3 mm | 550-800 |

| 2 – 3 mm | 500-750 |

| 2 – 5 mm | 500-750 |

| 3 – 5 mm | 450-700 |

Bubble alumina:

bubble alumina brick: