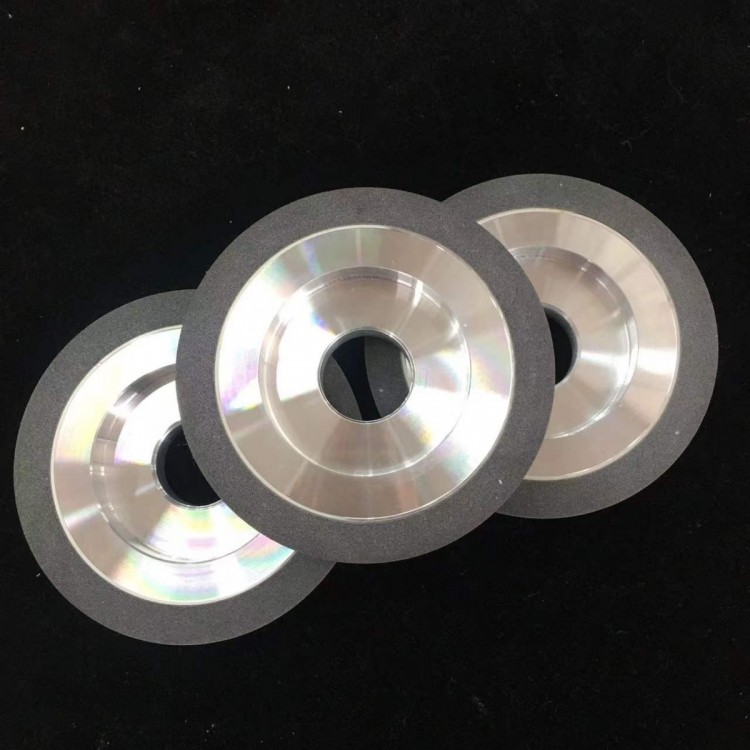

Hollow alumina spheres for CBN grinding wheel hole making

Why is “pore formation” so important?

Grinding wheels are not solid structures; the appropriate amount of pores inside is crucial. They primarily serve the following functions:

Cooling and heat dissipation: During grinding, pores effectively carry coolant into the grinding zone, carrying away a significant amount of heat and preventing burns to the workpiece and grinding wheel.

Chip containment and removal:They provide storage space for the fine chips generated during grinding and help them escape, preventing wheel clogging and maintaining sharpness.

Improved self-sharpening:They help dull abrasive grains detach promptly, allowing new, sharp abrasive grains to engage in the work, maintaining stable grinding efficiency.

Vibration absorption:They help reduce vibration during the grinding process, improving the surface finish.

Description:

Hollow alumina spheres have good high-temperature resistance, good insulation properties, good thermal shock resistance, and high strength. Since those materials have low bulk density and low thermal capacity, they can improve the thermal efficiency of high-temperature furnaces, shorten the production cycle and significantly reduce the furnace’s weight. It can be directly used in the linings of high-temperature furnaces.

Manufacturing Process – hollow alumina spheres

Alumina raw materials are melted in an electric arc furnace at 2200℃. When pouring the melt out, blow the melt with high-pressure air to make the melt dispersed into small droplets. During the cooling process, the droplets form alumina hollow balls due to surface tension effects. The hollow balls are screened to remove fine powder and big fragments and particles. Iron is removed with the magnetic iron. Broken balls are removed with a ball selecting machine. Then the alumina hollow spheres are packed as the finished products.

Chemcial data | ||||||||||

Size | Al2O3 | Fe2O3 | SiO2 | Na2O | MgO | K2O | Cao | |||

1-2mm | ≥99% | ≤0.15% | ≤0.3% | ≤0.5% | ≤0.1% | ≤0.1% | ≤0.1% | |||

Physical data | ||||||||||

Bulk density | Refractoriness | Appearance | ||||||||

0.5-1g/cm3 | 1800° | White hollow sphere | ||||||||

| | ||||||||||

Bulk density(g/cm3)

| Size | 5-4mm | 4-3mm | 3-2mm | 2-1mm | 1-0.5mm | 3-0.2mm | 0.5-0.2mm |

| g/cm3 | 0.45 | 0.55 | 0.65 | 0.75 | 0.85 | 0.85 | 0.95 |

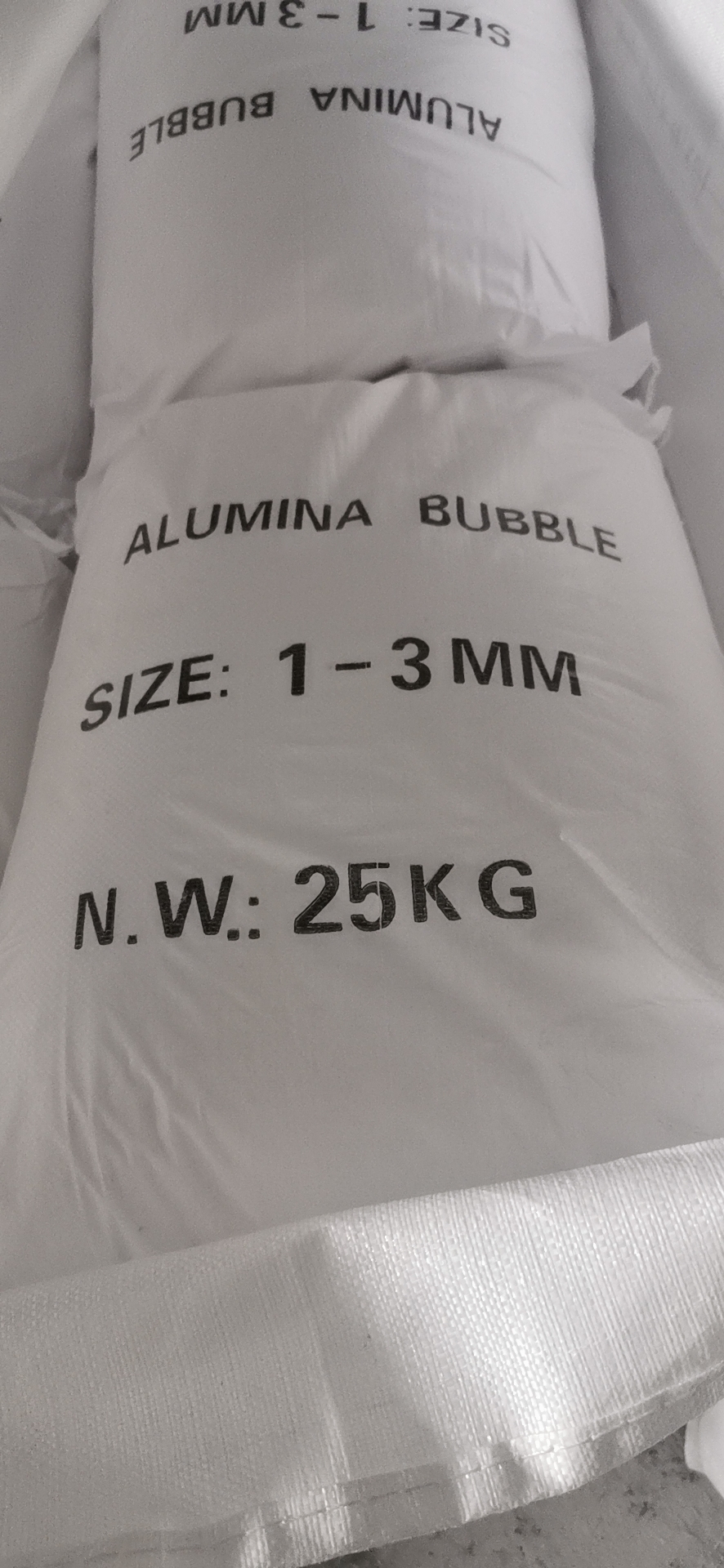

Bubble alumina package:

25kgs/pvc bag, 40 pvc bag/jumbo bag